Facility life rarely comes with a clean pause button. Whether you manage a manufacturing plant, hospital, data center, school, or any 24/7 operation, the phrase “just shut it down so we can check it” is rarely realistic. Downtime disrupts schedules, strains budgets, and creates risk of its own.

Infrared (IR) thermal imaging exists for exactly this reality. It’s a non-destructive testing method that detects abnormal heat patterns—often the earliest warning signs of electrical, mechanical, or building-envelope problems—while systems remain energized and operating. No teardown, no wall removal, and no shutdown windows that never seem to appear.

Below is what thermal imaging can uncover without disrupting operations and how facilities typically use it in preventive maintenance and compliance programs.

What non-disruptive testing really means

Thermal imaging cameras detect infrared radiation and translate it into a visual temperature map. In facilities, abnormal heat usually points to predictable root causes:

- Electrical resistance (loose connections, overloads, imbalance)

- Mechanical friction (bearing wear, misalignment, lubrication issues)

- Air and moisture movement (leaks, wet insulation, envelope defects)

Because these issues show up most clearly under load, IR inspections are commonly performed while equipment is running and processes are operating normally.

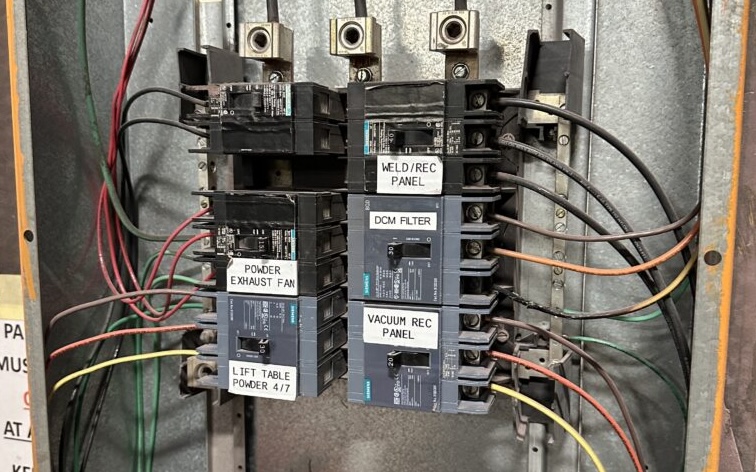

Electrical inspections on energized systems

Electrical problems rarely fail instantly. A loose termination or stressed breaker often runs warmer long before it trips, arcs, or shuts down a system.

On live electrical equipment, thermal imaging commonly identifies:

- Hot spots at terminations and connections

- Overloaded circuits and phase imbalance

- Failing breakers, fuses, and disconnects

- Transformer and bus issues

- Harmonic-related heating in panels and neutrals

Seeing equipment under real operating conditions provides insight that de-energized inspections can’t. A professional IR program also accounts for safety requirements, PPE, access rules, and documentation that supports maintenance planning and NFPA 70B-aligned preventive maintenance programs.

Mechanical equipment: catching wear early

Mechanical failures almost always give warning—if you’re looking. Bearings heat up as they degrade. Misalignment creates friction. Belt and coupling problems leave distinct thermal signatures.

Thermal imaging is commonly used on:

- Motors, pumps, fans, and blowers

- Gearboxes and conveyors

- Rollers and rotating support equipment

Typical findings include failing bearings, lubrication problems, misalignment, and electrical-to-mechanical crossover issues. While thermal imaging doesn’t replace vibration analysis or other predictive tools, it’s a fast, non-contact way to screen large numbers of assets and prioritize where deeper diagnostics are needed.

Building envelope and moisture investigations

In occupied buildings, opening walls or ceilings to investigate leaks or comfort complaints creates disruption, dust, and scheduling challenges. Thermal imaging helps narrow the search non-invasively.

Depending on conditions, IR can help identify:

- Moisture intrusion and wet materials

- Insulation voids or inconsistent coverage

- Air leakage around penetrations, doors, and windows

- Thermal bridging contributing to energy loss and comfort issues

This allows teams to investigate problems like recurring ceiling stains or hot/cold complaints with targeted repairs instead of guesswork—especially valuable for facilities that operate around the clock.

Where IR delivers the most value

Thermal imaging shines where downtime is costly or unacceptable:

- Data centers: electrical inspections without taking loads offline

- Cold storage and food processing: identify stress points without warming product zones

- Continuous manufacturing: scan MCCs, drives, and rotating assets during production

- Healthcare: investigate building issues without disrupting care areas

Integrating IR into routine maintenance

Thermal imaging doesn’t require major outage planning. Most facilities integrate scans into existing rhythms:

- During normal operating hours under typical load

- Around planned maintenance windows for access, not shutdown

- Before peak seasonal demand

- After electrical or mechanical changes

Common cadences include annual electrical surveys, periodic mechanical route scans, and as-needed building envelope investigations.

Turning findings into action

A useful IR program prioritizes findings by severity:

- Immediate/critical: safety risk or likely imminent failure

- High priority: abnormal condition needing prompt correction

- Monitor: minor anomaly to trend over time

This helps teams fix what matters most first, schedule the rest, and document what’s being monitored so nothing slips through the cracks.

The bottom line

You don’t have to choose between preventive maintenance and staying online. Infrared thermal imaging helps facilities detect developing electrical, mechanical, and building-envelope issues while equipment remains running—so repairs happen on your terms, not during emergencies.

Louisville Infrared Thermal Imaging provides high-resolution scans and clear, actionable reporting led by certified thermographer Jack McNear. If uptime is your constraint, IR helps you protect reliability without pulling the plug.